Achieving Sustainable biological Development

Carbon Footprintprint Certificated

With carbon footprint certification, we have a better understanding of our carbon emissions, formulated plans and strategies to reduce carbon emissions, and improved environmental awareness and market competitiveness. Low-carbon environmental protection technology always runs through the "full life cycle" of products, and will continue to lead the development of green technology in the industry and contribute to the world's green and low-carbon transformation and development!

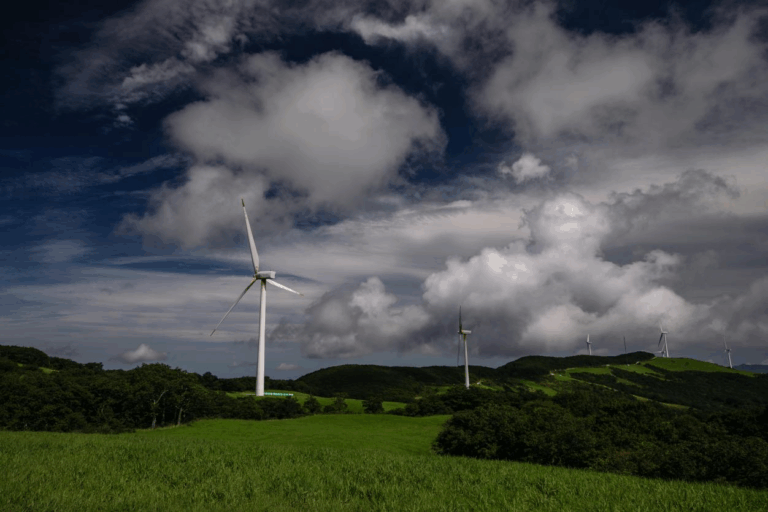

ECO-sustainability

ECO-sustainability is core to forward-thinking biotechs. Our materials source from organic, non-GMO suppliers to avoid ecological harm. In production, we replace traditional solvent extraction with eco-friendly biocatalysis—solvent-free, cutting energy use by 30%, slashing waste gas/residues. Wastewater is recycled (90% reused), packaging is recyclable/biodegradable, and by-products become organic fertilizer. This aligns with global standards, blending quality with eco-responsibility for sustainable growth.

Green production

eco-friendly biocatalytic extraction technology while streamlining traditional production workflows. Unlike conventional solvent extraction methods, this advanced approach eliminates the adverse effects of strong acids and alkalis—both on product quality and the environment. It also features solvent-free operation, low pollution levels, and reduced energy consumption, with minimal exhaust gas and residue generated throughout the process. This aligns seamlessly with Proxima’s commitment to sustainable development.

Sewage Treatment

Sewage Treatment is the greatest requirement for sustainable development in the company's production and operation, and it is also a sincere manifestation of the company's commitment to sustainable development. Since its establishment, NE Nutrition has considered green environmental protection as a fundamental requirement in the design of its production lines. The company has invested USD 3,000,000 in the construction of its sewage treatment facilities, which utilize a fully automated control system. The control process of the sewage treatment system is simple, with low work intensity.